Toollense – Optical Tool Inspection Right on the Shopfloor

Tool measurement must not be a luxury — or a time killer.

Your challenge

During setup and in ongoing production, conventional tool measurement costs time: walking to the measuring room, re-clamping, complex measuring systems — while the machine may be waiting instead of producing.

Our solution

Toollense brings razor-sharp tool measurement directly into production — right next to the machine. Fast, simple, and highly precise.

The proof

See it for yourself — live in our showroom or in a short video.

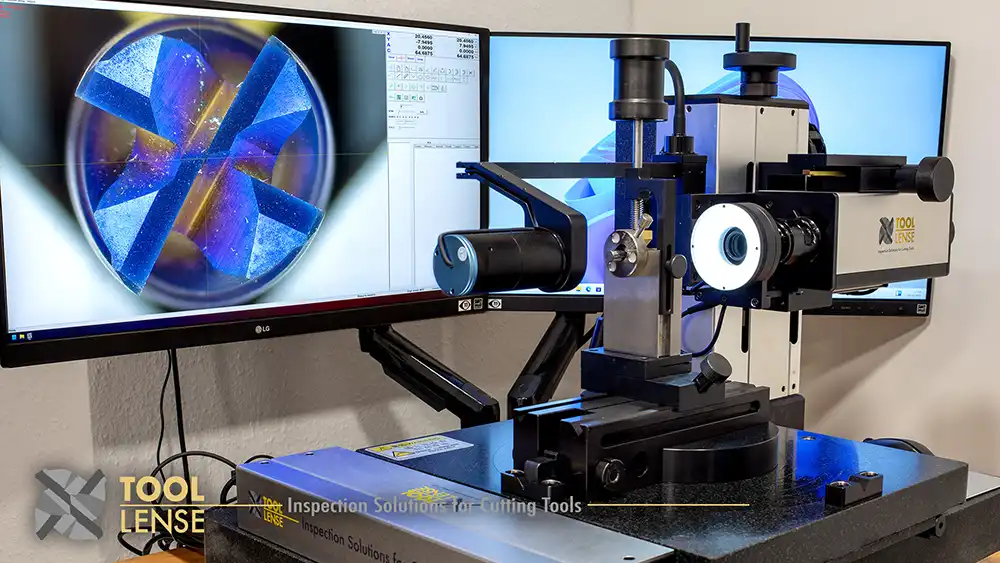

Toollense Type E - Ergonomic

Measure ergonomically. Decide fast. Produce with confidence.

Who is Type E for?

- Tool grinders with high daily throughput

- Quality assurance directly in production

- Users who want intuitive, fast results

⚙️ Why the Type E layout?

- Camera looks in the same direction as the operator

- Movements on screen match real movements

- Highly ergonomic access to all controls

Direct line-of-sight to the tool is slightly limited — in return, the operating logic is exceptionally clear.

Which configuration fits you?

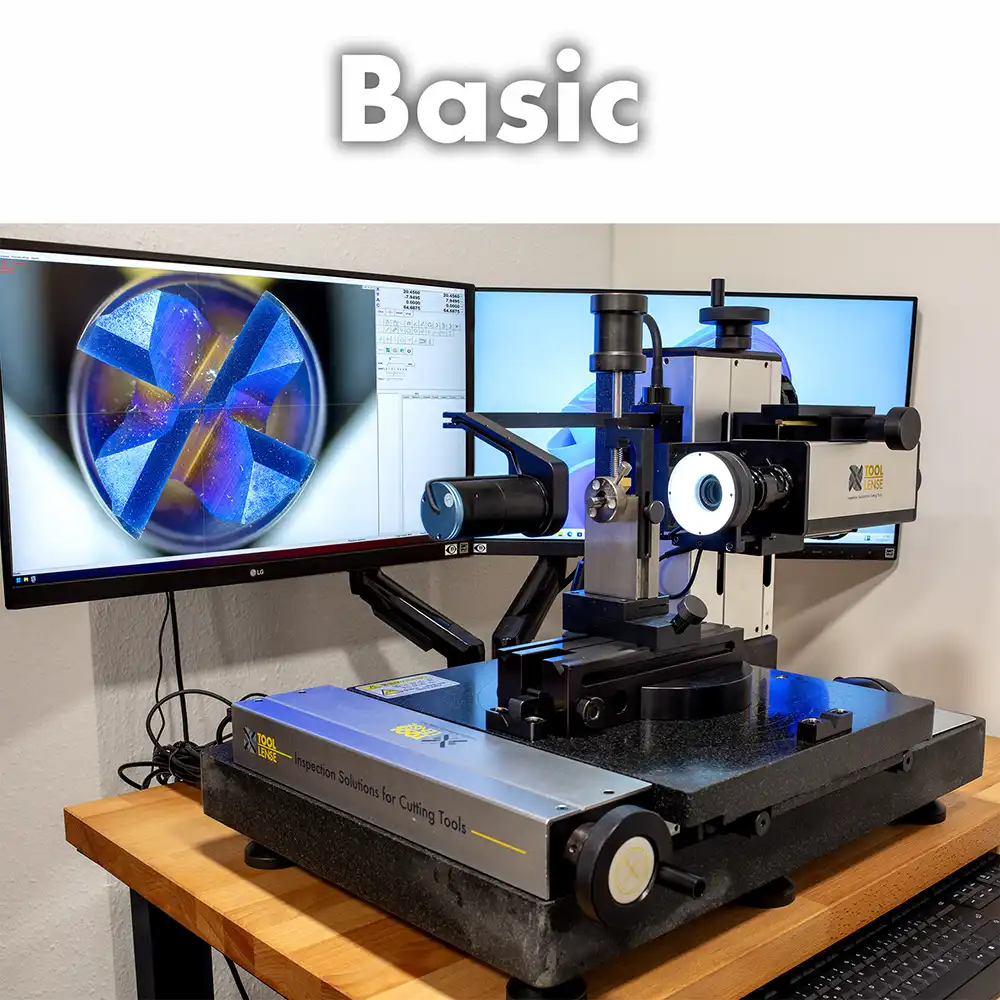

Basic – the measuring unit only

Basic – the measuring unit only

- Vision Software

- 3 Linearachsen (X/Y & C)

- Glass scales on all axes

- 4K – 300x

Advanced – even more clarity and comfort

Advanced – even more clarity and comfort

- Vision Plus Software

- Axially supported C-axis

- 5K – 450x

- 40" Curved

Professional – the measuring machine

Professional – the measuring machine

- Vision Plus Software

- Additional Z axis

(focus always under control) - Stationary complete setup

Typical applications

Fast manual measurement

EASY Diameter

End-face measurements

Toollense Type C - Compact

Compact design. Measure fast. Produce with confidence.

Who is Type C for?

- Tool grinders with high daily throughput

- Quality assurance directly in production

- Users who want intuitive, fast results

⚙️ Why the Type C layout?

- Clear line of sight to the tool

- Minimal footprint

- Besseres best value

The camera is positioned perpendicular to the operator’s view, so screen movement directions feel different — in exchange, you always have a clear view of your tool.

Which configuration fits you?

Basic – the measuring unit only

Basic – the measuring unit only

- Vision Software

- 3 Linearachsen (X/Y & C)

- Glass scales on all axes

- 4K – 300x

Advanced – even more clarity and comfort

Advanced – even more clarity and comfort

- Vision Plus Software

- Axially supported C-axis

- 5K – 450x

- 40" Curved

Professional – the measuring machine

Professional – the measuring machine

- Vision Plus Software

- Additional Z axis

(focus always under control) - Stationary complete setup

Typical applications

One-click measurement

End-face measurements

Easy runout

Toollense Type V – Pure Vision

Microscopes and magnifying glasses were yesterday —

Toollense Type V is today!

Who is Type V for?

- The revolution for everyone

- who still inspects with a magnifier or microscope

- Visual inspection of cutting tools

- purely visual inspection

- in production or

- final inspection

Many tools are still inspected manually with magnifiers, measuring microscopes, or improvised camera setups — slow, tiring, and extremely time-consuming.

🔍 Why Toollense Type V?

- Everything at a glance — end face & circumference at the same time

- 2 cameras & 2 screens

- Razor-sharp, live, and high-resolution in 4K

- Focus once — stay sharp

- Comfortable & ergonomic — no bending, no eye strain

From clamping to complete visual inspection in seconds. There is no faster way to perform visual inspection.

Pure Vision — what you really gain

- Visual inspection in seconds

- Circumference and end face at a glance

- No refocusing

- Razor-sharp 4K images

- Repeatable visual inspection

- No subjective judgment

- Comfortable on 2 screens

- No looking through an eyepiece

- Relaxed working

Visual inspection with Type V

Application Examples

Measuring can be this simple

Manual measurements

fast & easy with the crosshair

What can you measure?

- Diameters

- Angles

- Lengths

- Widths

The crosshair changes color as soon as an edge is reached. This gives the operator confidence and sustainably improves the accuracy of manual measurements.

Simple image overlay

Compare with a master tool

How does it work?

- Take a screenshot of the master

- Overlay the live image

- Spot deviations quickly

- DXF overlay also possible

Overlay the live image of the tool with a saved image of a master tool. Transparency is continuously adjustable. The overlay can also be done using a DXF file.

EASY diameter

Get the diameter in seconds

How does it work?

- Open the function

- Start the scan

- Rotate the tool

- Read out the diameter

Ultra-fast and highly precise determination of the running diameter across all cutting edges.

Ultra-precise diameters

using automatic edge detection

How does it work?

- Automatic detection of the cutting edge at top and bottom

- Determination of the highest point per cutting edge

- Calculation of the exact distance between both edges

With this method, diameters can be determined with high precision, excellent repeatability, and operator independence. The results reach an accuracy typically associated only with far more complex measuring systems.

EASY Runout

Runout check in seconds using automatic edge detection

How does it work?

- Open the EASY runout function

- Start the automatic scan

- Measurement points are captured automatically

- Runout is calculated and displayed immediately

EASY runout enables an extremely fast, repeatable runout check — without complex settings and independent of the operator.

Optical contour / circumference capture

with automatic image evaluation

A function many users from professional video measuring systems know as “CRIS”.

- Capture the complete running contour

- Automatic edge and contour detection

- Direct comparison to a DXF reference contour

- Detection of radius deviations down to 0.1 µm

Optical contour and circumference capture enables a highly precise comparison to existing DXF contours, providing maximum confidence when evaluating complex tool geometries.

One-click measurement

complete evaluations with one click

Once-defined measurements can be saved and rerun anytime with a single click.

- Complete measurement routines and elements are saved

- Automatic edge detection captures all relevant geometries

- All values are calculated in the background

- Results are available within seconds

One-click measurement is a particularly

time-saving and user-friendly feature.

It allows even less experienced operators to inspect

complex tools quickly, repeatably, and precisely.

Ideal for series inspections, shift changes, and use directly on the shopfloor.

FAQ – Toollense: Optical Measuring Device for Cutting Tools

Toollense is manufactured in China – but not by just any producer, rather by a highly specialized company that has been firmly established in the cutting tool manufacturing market since 2008. The development company employs around 20 experienced engineers and has been working exclusively on inspection systems for the tool industry for more than 17 years.

On this basis, the Toollense product line was developed in 2020 and successfully introduced. Today, numerous well-known tool manufacturers in China rely on this system – including Rollomatic, Vollmer, Walter, Sandvik and many others. Toollense therefore combines practical experience from the tool grinding market, technical specialization and continuous development specifically tailored to the requirements of tool manufacturers and grinding shops.

In China, the system is already firmly established. Many well-known tool manufacturers already rely on Toollense – including Rollomatic, Vollmer, Walter, Sandvik and numerous other companies.

For European users this means: mature technology developed from the real needs of tool grinders, stable and practice-proven software, high image quality thanks to modern camera and lighting technology, and an attractive price-performance ratio made possible by an efficient production structure.

Toollense thus combines Chinese manufacturing expertise with European sales, service and quality standards – and offers an attractive alternative to established measuring systems from other manufacturers.

Toollense focuses on particularly high-resolution imaging of cutting tools and on simple, efficient operation. The integrated 4K – and, depending on the model, even 5K – technology makes cutting edges and tool geometries visible in razor-sharp detail. On the basis of these images, the software enables manual and, in some cases, semi-automated measurements in the micron range.

Through the combination of high-resolution optics and intuitive software, Toollense offers many companies a fast and practice-oriented way to perform measuring and inspection tasks directly at the grinding machine or in quality assurance. In this way, Toollense can usefully complement existing inspection processes or make them more efficient.

Toollense places particular emphasis on high-resolution imaging of cutting tools and on simple, efficient operation. The integrated 4K – and, depending on the model, even 5K – technology makes cutting edges and tool geometries razor-sharp on screen. Based on these images, the software enables manual and partially automated measurements in the micron range.

Through this combination of high-resolution optics and intuitive software, Toollense offers many companies a fast and practice-oriented way to carry out measuring and inspection tasks directly at the grinding machine or in quality assurance. Toollense can thus usefully complement existing inspection processes or help make them more efficient.

In practice, Toollense is often used by users when a flexible, image-based solution for daily quality control and documentation of end mills, drills and special tools is required – especially directly at the grinding machine or in the production area, as a complement to existing measuring processes.

In practice, Toollense is often used by users when a flexible, image-based solution for daily quality control and documentation of end mills, drills and special tools is required – especially directly at the grinding machine or in the production area, as a complement to existing measuring processes.

- need fast, simple and precise quality control directly next to the grinding machine,

- want to inspect tool geometries and cutting edges with high magnification and razor-sharp imaging,

- prefer intuitive, easy-to-learn software,

- want to use an optical inspection solution as a complement or alternative to existing measuring devices from other manufacturers (e.g. Zoller pomBasic, Zoller Genius, Walter Helicheck, PG1000, Marcel Aubert).

Type C plus: higher resolution, new software, additional measuring axis

Type V: purely visual inspection without measuring function